TRE820 – Compact ignition transformer

Compact inductive ignition transformer for gas and oil burners.

Insulated secondary winding suitable for single rod operation. Switchover between ignition and flame detection is performed by the burner control unit.

POWER SUPPLY INLET

CABLE

3 poles – 380 mm

HI VOLTAGE OUT VIRAS

flush self–tapping screw

18 mm deep

HI VOLTAGE OUT SPRAS

plug Ø 4 mm with sleeve

23 mm deep

| ORDER CODE | DESCRIPTION | NOTE |

|---|---|---|

| 1810.40.00 |

TRE820PISO 230VAC VIRAS Compact ignition transformer – 230Vac screw |

ACTIVE |

| 1810.30.00 |

TRE820PISO 115VAC VIRAS Compact ignition transformer – 115Vac screw |

ACTIVE |

| 1810.40.01 |

TRE820PISO 230VAC SPRAS Compact ignition transformer – 230Vac plug |

ACTIVE |

| 1810.30.01 |

TRE820PISO 115VAC SPRAS Compact ignition transformer – 115Vac plug |

ACTIVE |

| 1840.01.01 |

HI VOLTAGE CABLE 1300mm | 2 plugs Silicone/Copper 1mm2 20kV -50 +180°C Overmolded 4mm plug – 6.3mm rod plug 90° |

ACTIVE |

| 1840.01.02 |

HI VOLTAGE CABLE 1800mm | 2 plugs Silicone/Copper 1mm2 20kV -50 +180°C Overmolded 4mm plug – 6.3mm rod plug 90° |

ACTIVE |

| 1840.01.03 |

HI VOLTAGE CABLE 1800mm | 1 plug Silicone/Copper 1mm2 20kV -50 +180°C loose end – 6.3mm rod plug 90° |

ACTIVE |

Use unscreened high-voltage cable for the ignition cable: the spark intensity is lower when using a screened cable.

Keep the ignition cable as short as possible: the longer the ignition cable, the lower the spark intensity and greater the generated electrical interferences.

Plugs with integrated 1 kΩ resistor could be optionally used to reduce radio interferences.

A reliable connection to ground must be provided for the transformer and the burner frame, recommended wire gauge > 4 mm2.

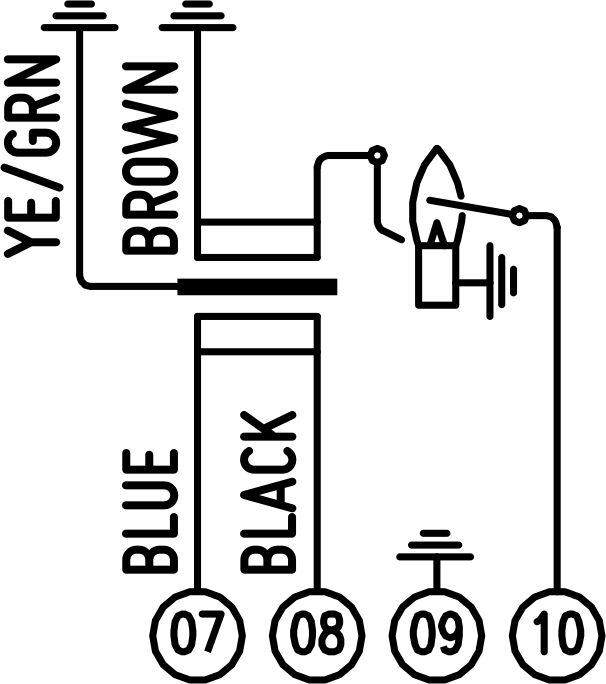

2 INDEPENDENT RODS |

|---|

|

BLUE WIRE NEUTRAL – QBK TERMINAL 07 |

|

BLACK WIRE PHASE – QBK TERMINAL 08 |

|

YELLOW GREEN WIRE CONNECT TO GROUND |

|

BROWN WIRE SEC RETURN – CONNECT TO GROUND |

The high voltage creates a spark between the ignition electrode and burner ground.

The flame current flows from the dedicated electrode into the control unit.

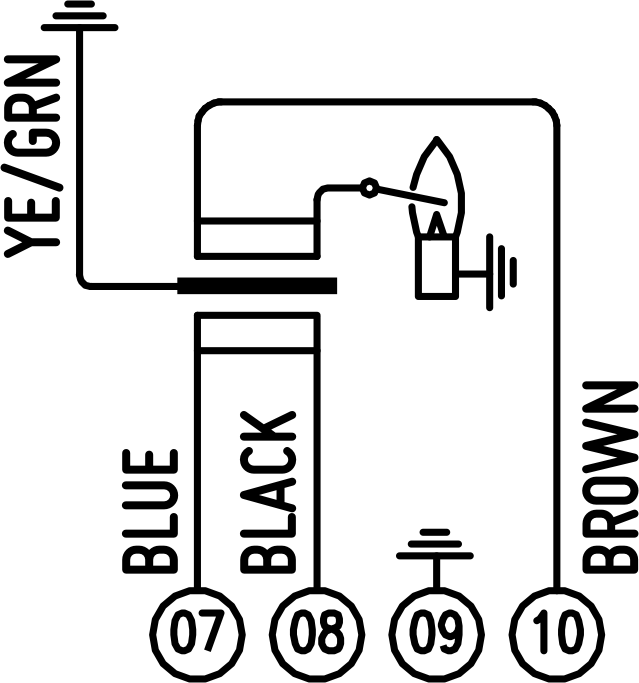

1 SHARED ROD |

|---|

|

BLUE WIRE NEUTRAL – QBK TERMINAL 07 |

|

BLACK WIRE PHASE – QBK TERMINAL 08 |

|

YELLOW GREEN WIRE CONNECT TO GROUND |

|

BROWN WIRE SEC RETURN – QBK TERMINAL 10 |

A single electrode used for both ignition and flame detection.

Electrode switched to ground during the ignition. The flame current flows from the electrode through the secondary winding into the control unit.

EASY TO FIT

Four holes for self tapping screws are available to install the ignition transformer directly on the back of the QBK enclosure.

The high voltage cable is fully accessible without opening the box.

Eight breakable holes for strain reliefs or glands are available for cables exit.

Using this solution the accessible front is clean and it's possible to install several controls side by side.

- • Primary Supply Voltage230 VAC

- 115 VAC

- • Primary Supply Current1 A @ 230V

- 1,9 A @ 115V

- • Frequency50 … 60 Hz

- • Power230 VA

- • Secondary Voltage 18 kV ±10% RMS

- • Secondary Peak Voltage 111 kV

- • Secondary Current 220 mA ±10% RMS

- • Duty cycle19% 3 minutes

- • Enclosureepoxy thermosetting resin

- • Operating Temperature35°C

- • Temperature ClassB

- • Protection ClassIP00

- • Weight1900 g

- • Ignition cable length< 5 m

- • Recommended spark gap3 … 5 mm

- • Mounting Position ANY

1 OPEN CIRCUIT

2 SHORT CIRCUIT

The duty cycle indicates for how long the ignition transformer can operate within 180 s.

Max operating time = Duty cycle [%] × 180 s / 100%

Considering 19% duty cycle of TRE820, the maximum operating time is 34 s within 3 minutes.

This means a maximum of 2 ignitions of 5 seconds each are allowed per minute without damages.