QBK FULL – 1 or 2 stages + process inputs / outputs

• Natural or forced draught gas burners.

• Blue flame oil burners.

• Single stage burners.

• Dual stage burners.

• Flame detection by means of UV sensor, dual or single electrode.

• Air valve or fan output, following cycle or independently controllable.

• Low air pressure switch.

• Burner ON output.

• Burner LOCKOUT output.

• Remote RESET input.

• Remote AIR control input

• THERMOSTAT 1 input for remote burner control.

• THERMOSTAT 2 input for independent main burner control.

• High-temperature option for flame surveillance bypass.

• Optional independent main flame supervision.

• Built-in fieldbus control.

• Infrared commissioning interface (smartphone app).

• Led-bar flame signal indicator.

• Independent and configurable flame sensitivity for pilot and main burners.

• Advanced self-diagnostic report of cycle status, lockouts and failures.

• Log memory for lockouts and faults.

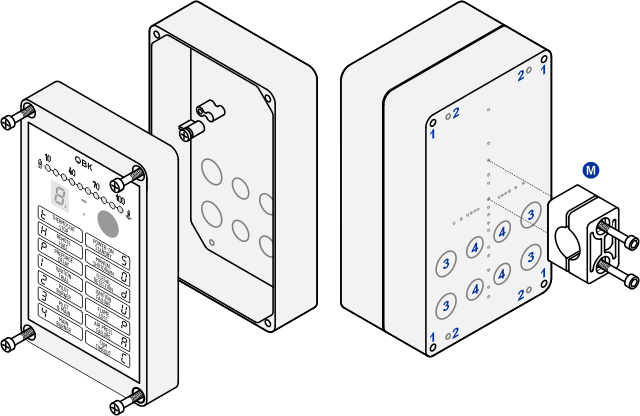

| FRONT PANEL | |

|---|---|

| FITTING SCREWS | 1 |

| FLAME SIGNAL BARGRAPH – RED | 2 |

| STATUS DISPLAY | 3 |

| RESET / SHUTOFF BUTTON | 4 |

| COM INDICATOR – YELLOW | 5 |

| AIR OUTPUT INDICATOR – BLUE | 6 |

| HI-TEMP BYPASS INDICATOR – RED | 7 |

| INTERNAL | |

|---|---|

| 8 | MAIN TERMINAL BOARD |

| 9 | POWER SUPPLY FUSE 1 |

| 10 | INPUT/OUTPUT TERMINAL BOARD |

| 11 | INPUT VOLTAGE SPECIFICATION |

| 1 | ULTIMATE PROTECTION AGAINST DANGEROUS CONDITIONS BY MEANS OF INTERNAL NON REPLACEABLE 5A SAFETY FUSE |

| ORDER CODE | DESCRIPTION | NOTE |

|---|---|---|

| 1488.33.PF |

QBK FULL 115 115 PLASTIC Power supply 115V – Process inputs 115V |

ACTIVE |

| 1488.34.PF |

QBK FULL 115 230 PLASTIC Power supply 115V – Process inputs 230V |

ORDER RELATED |

| 1488.32.PF |

QBK FULL 115 24 PLASTIC Power supply 115V – Process inputs 24V |

ORDER RELATED |

| 1488.44.PF |

QBK FULL 230 230 PLASTIC Power supply 230V – Process inputs 230V |

ACTIVE |

| 1488.43.PF |

QBK FULL 230 115 PLASTIC Power supply 230V – Process inputs 115V |

ORDER RELATED |

| 1488.42.PF |

QBK FULL 230 24 PLASTIC Power supply 230V – Process inputs 24V |

ORDER RELATED |

| 1488.33.0F |

QBK FULL 115 115 ALUMINIUM Power supply 115V – Process inputs 115V |

ACTIVE |

| 1488.34.0F |

QBK FULL 115 230 ALUMINIUM Power supply 115V – Process inputs 230V |

ORDER RELATED |

| 1488.32.0F |

QBK FULL 115 24 ALUMINIUM Power supply 115V – Process inputs 24V |

ORDER RELATED |

| 1488.44.0F |

QBK FULL 230 230 ALUMINIUM Power supply 230V – Process inputs 230V |

ACTIVE |

| 1488.43.0F |

QBK FULL 230 115 ALUMINIUM Power supply 230V – Process inputs 115V |

ORDER RELATED |

| 1488.42.0F |

QBK FULL 230 24 ALUMINIUM Power supply 230V – Process inputs 24V |

ORDER RELATED |

ORDER CODE MUST BE COMPLETED WITH CONFIGURATION CODE

A JUMPER MUST BE INSTALLED BETWEEN TERMINALS A1•A2 WHEN THE AIR PRESSURE SWITCH IS NOT AVAILABLE AND AIR OUTPUT VA IS ENABLED

THE OUTPUTS AT TERMINALS 11 AND 12 ARE SPST UNPROTECTED DRY CONTACTS

LOAD MUST BE WITHIN THE RATED CURRENT

PROVIDE RELIABLE CONNECTION TO PE (PROTECTION EARTH) AND BURNER FRAME

RECOMMENDED WIRE GAUGE > 4 mm2

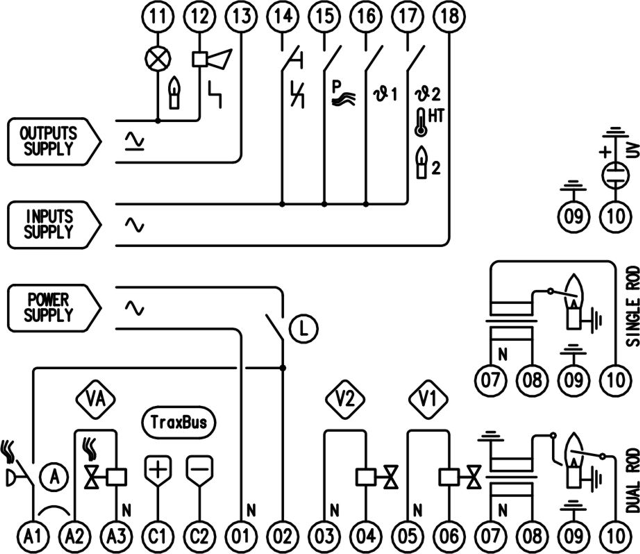

| LOW AIR PRESS SWITCH INPUT | A1 |

|---|---|

| AIR VALVE OUTPUT – L | A2 |

| AIR VALVE OUTPUT – N | A3 |

| COM INTERFACE – POSITIVE | C1 |

| COM INTERFACE – NEGATIVE | C2 |

| POWER SUPPLY – N | 01 |

| POWER SUPPLY – L | 02 |

| MAIN VALVE – N | 03 |

| MAIN VALVE – L | 04 |

| PILOT VALVE – N | 05 |

| PILOT VALVE – L | 06 |

| IGNITION TRANSFORMER – N | 07 |

| IGNITION TRANSFORMER – L | 08 |

| GROUND | 09 |

| FLAME SENSOR INPUT | 10 |

| 11 | ► OUTPUT BURNER ON |

|---|---|

| 12 | ► OUTPUT BURNER LOCKOUT |

| 13 | ► OUTPUTS COMMON |

| 14 | ◀ INPUT RESET |

| 15 | ◀ INPUT AIR CONTROL |

| 16 | ◀ INPUT THERMOSTAT 1 |

| 17 | ◀ INPUT THERMOSTAT 2 |

| ◀ INPUT HITEMP BYPASS | |

| ◀ 2ND FLAME SENSOR | |

| 18 | ◀ INPUTS COMMON |

| A | LOW AIR PRESSURE SWITCH |

| L | EXTERNAL LIMITS |

| VA | AIR VALVE (FAN) |

| V1 | PILOT FUEL VALVE |

| V2 | MAIN FUEL VALVE |

Power supply

- • Voltage115 or 230 V +10-15%

- • Frequency50/60 Hz

- • Line FuseQUICK 3 A

- • Power Consumption< 6 VA

- • Power Dissipation< 4 W

Environment

- • Operating Temperature-20...+60°C

- • Storage Temperature-40...+85°C

- • Relative HumidityNO CONDENSATION

- • Protection ClassIP64 / NEMA3

- • WeightAPPROX 1100 g

- • Mounting Position ANY

Outputs

- • Max rated Voltage250 VAC

- • Max switching Voltage440 VAC

- • Max Load (per output)2 A PF=70%

Air pressure switch input

- • Current< 3 mA

Process Inputs

- • Rated Voltage230, 115, 48, 24 V

- • Current< 3 mA

Flame detection

- • Minimum ionization Current> 1 μA

- • Current limitation< 3 mA

- • Signal Display0...100% | 0...30 μA

- • Detector Line Length< 30 m

- • Single Rod Line Length< 2 m

- • Detector Voltage< 250 VAC

- • Detector Insulation> 50 MΩ

- • UV SensorUV4SH

TraxBus Com Interface

- • Voltage< 30 VDC

- • Baud Rate4800, 9600, 19200, 38400

| EXTERNAL FITTING HOLES | 1 |

|---|---|

| BREAKABLE FITTING HOLES | 2 |

| BREAKABLE PG11 HOLES FOR WIRING | 3 |

| BREAKABLE PG9 HOLES FOR WIRING | 4 |

| M | OPTIONAL PIPE FITTING CLAMP |

|---|---|

| CAST ALUMINUM ALLOY EN AB 46100 or

THERMOPLASTIC POLYMER BLEND UL-V0

OVERALL DIMENSION: 200 x 120 x 71 mm EXTERNAL COATING GRAY RAL9006 |

|

QBK is fully confgurable: the same device can be used to control different types of gas and oil burners. Password is required to modify all parameters except for Communication settings.

GENERAL SETTINGS

001 • POWER SUPPLY VOLTAGE

002 • PROCESS INPUTS VOLTAGE

003 • BURNER TYPE

004 • INPUT TERMINAL 17

005 • AIR SWITCH RESPONSE TIME

AT POWER ON – LOCKOUT

101 • START-UP MODE

102 • AIR OUTPUT

DURING SHUTDOWN

201 • MINIMUM PAUSE TIME

202 • AIR OUTPUT

DURING PREPURGE

301 • AIR RUN-UP TIME

302 • AIR OUTPUT

303 • PREPURGE TIME

DURING IGNITION

401 • PRE-IGNITION TIME

402 • FIRST SAFETY TIME

403 • PILOT STARTUP ATTEMPTS

404 • PILOT FLAME SENSITIVITY

DURING OPERATION

501 • PILOT PROVING PERIOD

502 • SECOND SAFETY TIME

503 • MAIN FLAME SENSITIVITY

504 • FLAME FAILURE

505 • FLAME FAIL RESPONSE TIME

506 • AIR OUTPUT

507 • AIR FAILURE

508 • MIN COMBUSTION TIME

509 • POST-COMBUSTION TIME

DURING POSTPURGE

601 • AIR OUTPUT

602 • POSTPURGE TIME

COMMUNICATION SETTINGS

701 • ZONE (SEGMENT)

702 • UNIT (NODE)

703 • BAUD RATE

704 • TIMEOUT

Customers that want to modify the configuration can apply for specific agreement here. Once approved, all purchased units will have unique password assigned. Since a new label or remark must be placed on the unit when the original configuration is modified, this procedure is not recommended for occasional users.

Configuration code with default settings (red)

Note on EC type-examination

Since EN 298 does not describe all functions of the QBK – implemented to manage all possible industrial scenarios – the operator is responsible for ensuring that parameters and functions are appropriate for the application.

Certification applies only for options and values allowed by EN-298.